Using Festo Didactics patented Quick-Fix mounting system together with the profile plates, all Most of the pneumatic components are assembled on the patented Quick-Fix mounting system. Pneumatic pressure, non-return and flow control valves Pneumatic directional control valves, sequence control Pneumatic power components for linear movements Logic operations: explaining and implementing AND/OR/NOT operationsĮconomic considerations of using pneumatic componentsįundamentals and terminology of control technology

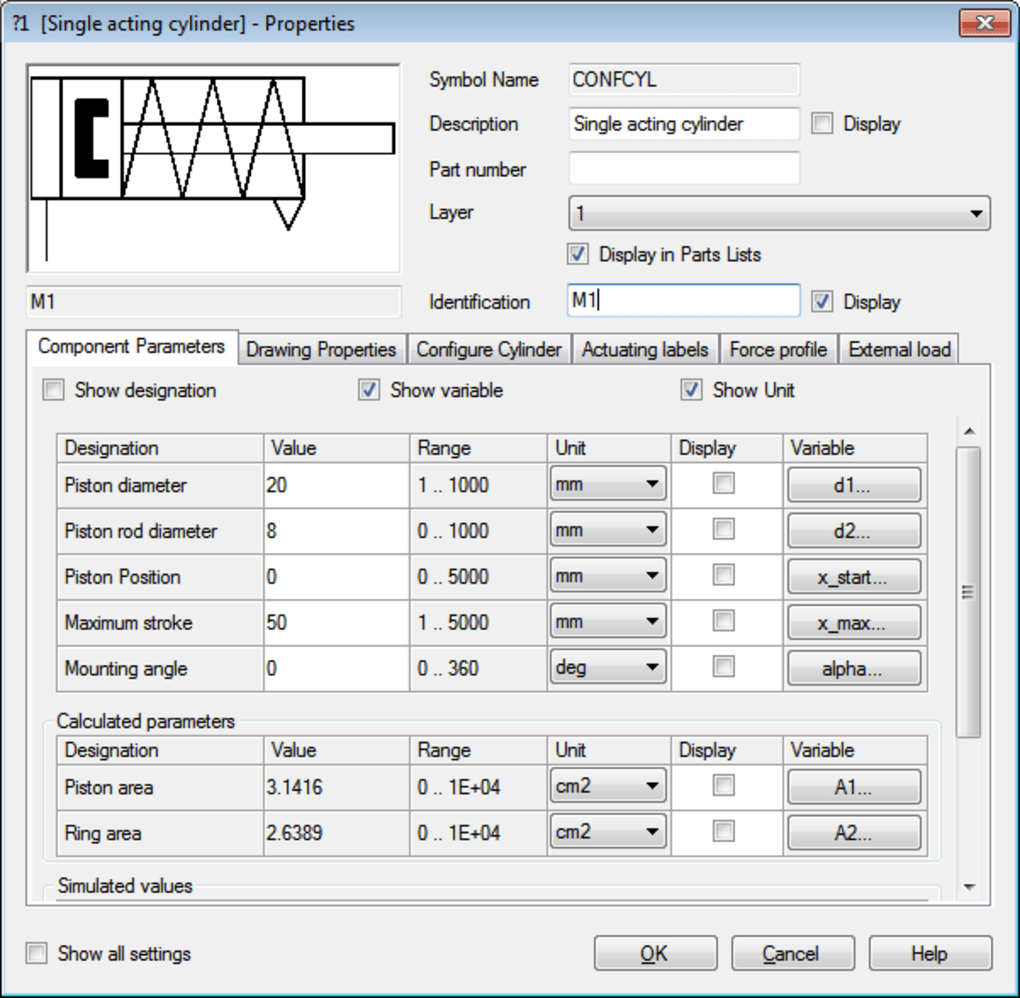

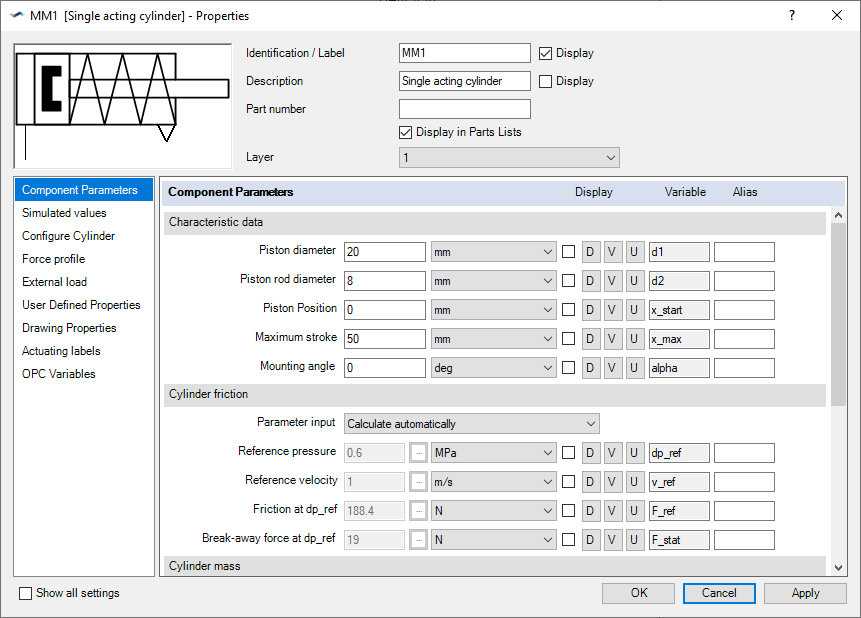

Methods of actuation of directional control valvesĭistinguishing flow control methods and using them as intendedĮxplaining and building latching circuits Structure, function and application of single-acting and double-acting cylindersĪpplication and function of 3/2 and 5/2-way valves The set of equipment enables the construction of simple pneumatic control circuits. Knowledge on the physical fundamentals of pneumatics as well as of the function and application of pneumatic components is conveyed. To be able to conduct sustainable training, especially whereby hands-on training cannot be neglected, it is indispensable to provide adequate training equipment and facilities with Festo Pneumatic Trainer Kit for the trainer as well as for students.īasic Level TP101 provides initial training in pneumatic control technology. Pneumatic Training Kit for Engineering Colleges, Polytechnics & Vocational Institutes

Learning supported by AR and QR technologies.Straightforward introduction to Manufacturing Execution Systems (MES).Comprehensive introduction to RFID technology and service-oriented architectures (SOA).Communication of customer-specific manufacturing processes through digital product memory.The subsequent joining station reads the RFID tag and decides what to do with the workpiece depending on the work order, and then writes the result to the tag.At the final sorting station, the workpieces are distributed to the three chutes depending on the information which has been saved to the RFID tag.

The entire system is networked and additionally equipped with several RFID write/ read heads.The system processes work orders which have been generated by the MES.A workpiece is separated in the first station and data is then written to its memory by an RFID sensor. The MPS® 203 I4.0 system is a modular production line comprising distribution/conveyor, joining and sorting stations. Introduction to Industry 4.0 for Mechatronics technicians

0 kommentar(er)

0 kommentar(er)